Building Resilience For a Harris County Waterway

An unusually shaped section of a tributary channel in North Houston had repeatedly been battered by severe storms, including Hurricane Harvey. Recurring erosion damages resulted, and temporary solutions often got carried away by stormwater.

Freese and Nichols worked with the Harris County Flood Control District on a longer-lasting repair to safeguard against future flood risks, improve the channel reach’s resilience and add innovative features for continued observation and maintenance of the area. The design team assembled to work with HCFCD on this project drew upon expertise from both the Stormwater and Water Resource Design practices.

The Problem

Located approximately 1,400 feet upstream of Cypress Creek in Harris County, a 420-foot-long reach of the K117-00-00 tributary channel navigates a bend of approximately 90 degrees paired with a 10-foot drop in flowline elevation. The configuration makes the channel reach particularly prone to erosion damages.

The original armoring system was typical for Harris County stormwater drainage channels: a combination of 8-inch-thick reinforced concrete channel lining and an 18-inch-thick layer of rock riprap with underlying geotextile fabric. But this channel reach’s unique geometry made it vulnerable, and repairs after the Tax Day Storm (April 2016), Hurricane Harvey (August 2017) and Tropical Storm Imelda (September 2019) did not last long.

The Solution

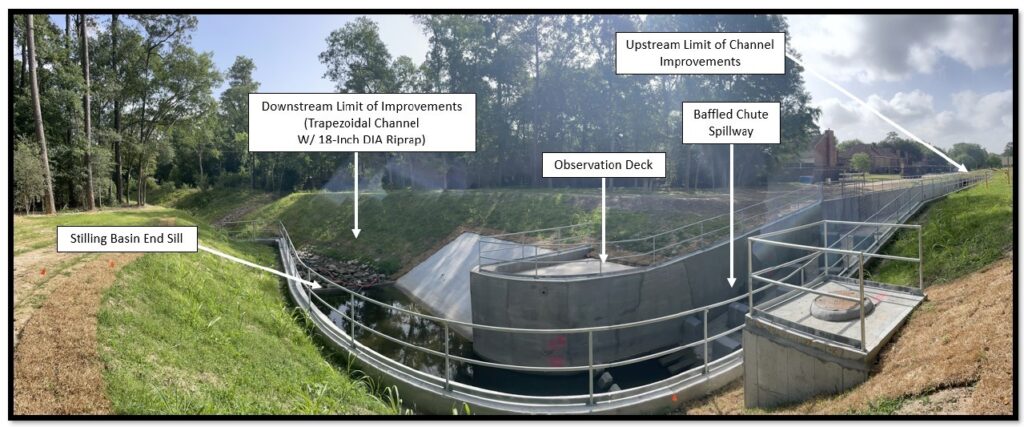

The Freese and Nichols team designed a rectangular, reinforced concrete channel with a baffled chute spillway structure and stilling basin hydraulic energy dissipation structure downstream. This system has effectively tackled the types of issues encountered at the site. The stilling basin was designed to curve to match the natural meandering of the channel bend and comply with HCFCD right-of-way requirements.

A subsurface drainage system was designed along the backside of the walls and underneath the channel slabs to manage groundwater and mitigate hydrostatic pressures in the soil that could compromise stability. This system incorporated geocomposite strip drains and a granular drainage package that surrounded the channel geometry and was enclosed by geotextile material.

The Innovation

The design accommodated several site constraints in ways that reduced complications, such as the need for utility relocations and right-of-way acquisition. For example:

- The reinforced concrete components were designed to retain the in-situ soils to reduce the cost associated with imported fill.

- The overbanks incorporated repurposed rock riprap from the original channel to help reinforce the slopes and fit the channel footprint within the right-of-way.

- The new footprint coincided almost exactly with the original, and part of the cross-section was carefully designed to accommodate an adjustment to an important gravity sanitary sewer located directly beneath the channel, avoiding a complete relocation of the sewer line.

While maintenance roads run along both channel overbanks, HCFCD staff could not access the channel bottom safely and reliably to clear potential obstructions or otherwise observe channel operations, so the design team incorporated these elements:

- A swing gate and access ladder system for maintenance crews to access the channel bottom.

- An observation deck to provide a bird’s-eye view inspection of the channel and baffled chute spillway during a storm event.

- Safety railing (with toe boards) to provide fall protection above the rectangular channel along both overbanks.

To design the new channel and accompanying spillway structure, the design team engaged subject-matter experts from the Stormwater and Water Resource Design practices. The hydraulic performance of the designed channel was validated by modeling performed in HEC-RAS, as well as using a Computational Fluid Dynamics model in Flow3D.

The spillway design was guided by criteria established by the United States Bureau of Reclamation. The geotechnical and structural evaluations performed were with reference to U.S. Army Corps of Engineers design guidelines. The channel geometry and its associated grading plan were configured intelligently using AutoCAD Civil3D capabilities.

In addition to improving resilience, the repairs helped HCFCD demonstrate its commitment to reducing flooding risks for Harris County neighborhoods, particularly residents who had directly suffered from the historical flooding in the K117-00-00 channel reach.

This project recently won a Horizon Award, a quarterly award at Freese and Nichols given to projects that encapsulate our culture of innovation.