Channel Walls: Finding the Right Type

The Delaware Creek Channel Improvements project, a $50 million project for the City of Irving, utilizes three types of channel wall available. Let’s take a look at the advantages and disadvantages, such as space, construction and speed.

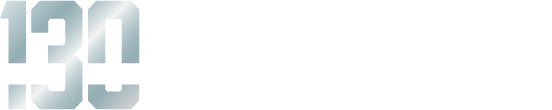

Modular Block Wall

Modular Block Wall

These walls are constructed by stacking precast concrete block units. These are gravity walls and resist external forces by their own self weight. Our site consists of fat clays and the walls are fairly tall – leading to the need for field cast extensions behind the wall, resulting in some pretty massive sections.

Advantages: One of the nice things about these walls is that they look nice because they are typically precast with a textured facing. They are also fairly quick to construct. At taller heights these walls become cost inefficient as the sections become exponentially more massive. The fixed wall height increments of the blocks can also lead to grading issues where yards don’t match up well to the wall elevation.

Disadvantages: The biggest downside for our project was the space these walls take up.

Cast-In-Place Walls

Cast-In-Place Walls

Cast-in-place concrete stem walls have a vertical stem with steel reinforcing to transfer forces from the retained earth to the footer. For our project, we located the footer in front of the stem to minimize excavation and to serve as the channel bottom.

Advantages: The walls require much less material and excavation than the modular block walls.

Disadvantages: The downsides are the time and labor it takes to set up the forms and reinforcing for concrete pours. This can lead to large sections of the channel that are at risk during a flooding event. These walls were used in areas with very narrow easements. One of the big concerns for the City was the look of this wall, but we were able to use form liners to make the wall look very similar to the modular blocks.

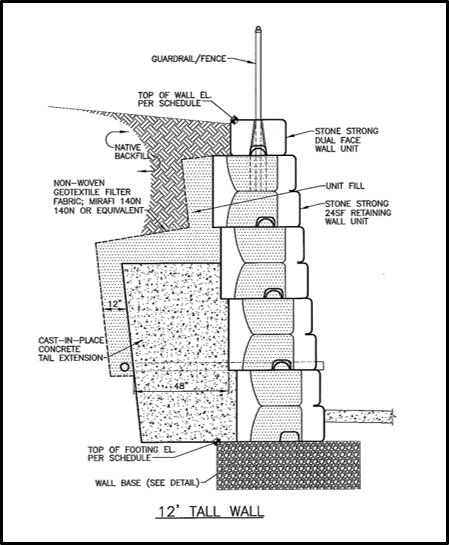

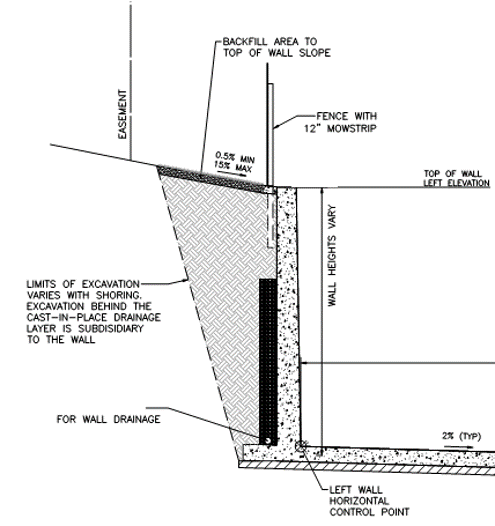

Soil Nail Wall

Soil Nail Wall

To construct this type of wall, holes are drilled into the face of the excavation spaced a few feet apart and steel bars are inserted with the annular space filled with grout. This reinforces the soil mass and essentially turns the soil mass into a large gravity wall.

Advantages: This wall requires very minimal cut beyond the wall face, and the slope is shored as the wall is constructed — leaving very little risk for damage to structures or from flooding.

Disadvantage: The downside to this wall type is the significant subsurface easement required for the soil nails.