The Right Direction: Vertical Versus Horizontal Pump Stations

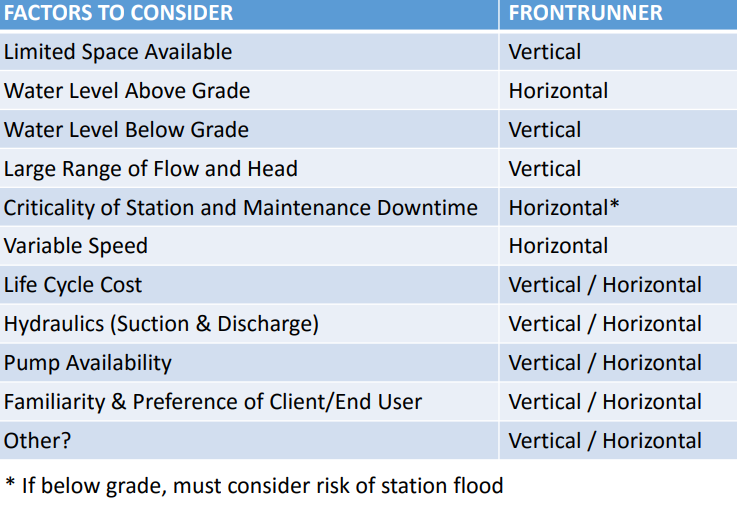

One of the first steps in pump-station design is to determine what type of pump station best suits the system’s needs.

The type of pump station sets the stage for the design of the entire facility. Some specific design items the designer will need to consider when selecting a type of pump station include: system curve, initial demand and expansion requirements, pump availability, storage requirements, NPSH available, maintenance and cost.

The type of pump station sets the stage for the design of the entire facility. Some specific design items the designer will need to consider when selecting a type of pump station include: system curve, initial demand and expansion requirements, pump availability, storage requirements, NPSH available, maintenance and cost.

Vertical turbine and horizontal split case centrifugal pumps are the most common types of pumps utilized in water applications.

Typical system curves for horizontal and vertical pumps lend themselves to certain applications based on system coverage. Vertical Turbine pump curves are typically rather steep and can cover a wide range of heads while horizontal pump curves are typically flatter and can cover a wide range of flows. Certain criteria are also critical for an Owner to consider when selecting a type of pump station: capital and life cycle cost, potential failure modes, and maintenance activities.

Here are how horizontal split case pumps and vertical turbine pumps stack up.

Advantages of horizontal split case pump:

- Ease of maintenance – Fewer bearings, removable casing, easy access, shorter duration of downtime

- Generally longer life

- High efficiencies

- Various suction orientations – flexibility in station arrangement

- Mechanically stable at variable speeds

- Lower cost if water level is above grade

Disadvantages of horizontal split case pump:

- Larger station footprint typically

- Pump and appurtenances must be below water level

- Below grade – subject to flooding

- Capacity and head only added with additional or replacement pumps

Advantages of vertical turbine pump:

- Smaller station footprint

- Ability to add head with stages

- Naturally steeper curve can cover large head range

Disadvantages of vertical turbine pump:

- Maintenance burden: large number of parts, harder to access pumping equipment, increased maintenance downtime

- Lower efficiencies

- Requires additional study if used in variable speed applications

Frequently an Owner may have a very strong opinion about the type of pump station design preference, but it is incumbent on the designer to bring other ideas that will be well-suited to the application.